Driving Perfection: Precision Engineering Inspection & Metrology in Malaysia

As Malaysia’s aerospace, medical device, and specialised tooling sectors—centred in the vibrant hubs of Penang and Selangor—reach new heights of complexity, the need for “zero-defect” manufacturing has never been more critical.

Vision Engineering Malaysia provides the world’s most advanced ergonomic 3D visualisation and non-contact measurement systems. We help Malaysian engineers bridge the gap between human intuition and micron-level digital precision.

The Precision Engineering Suite

Our systems are designed to improve yield, reduce scrap, and protect operator health in the most demanding production environments.

1. NEW: ProteQ VISO | The Future of 3D Digital Inspection

The ProteQ VISO is our latest breakthrough, bringing true glasses-free 3D stereo vision to a digital platform.

See in 3D, naturally: An integrated “autostereo” display allows you to view components in high-definition 3D without headsets or glasses.

Collaborative Engineering: Stream live 3D images from your lab in Subang Jaya to headquarters or customers anywhere in the world for instant approval.

Unmatched Ergonomics: The upright viewing position reduces neck strain and eye fatigue, ensuring accuracy throughout long shifts.

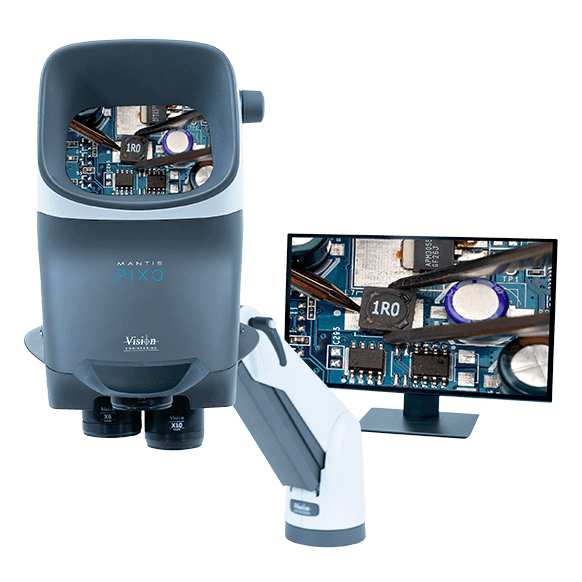

2. Mantis (3rd Gen) | The Industry Standard for Rework

The world-renowned “eyepiece-less” stereo microscope. Perfect for deburring, finishing, and inspecting precision-machined parts with natural hand-eye coordination.

3. Swift PRO & LVC Series | Non-Contact Metrology

From manual 3-axis measurement to fully automated CNC routines, our metrology systems provide the high-accuracy data required for IATF 16949 and ISO 13485 compliance.

Application Focus: Technical Cleanliness & Aerospace Quality

| Industry | The Challenge | Our Solution |

| Aerospace (Penang/Subang) | Identifying microscopic burrs and cooling hole blockages. | ProteQ VISO for immersive 3D depth perception. |

| Medical Devices (Bayan Lepas) | Inspecting catheter braiding and stent geometries. | Mantis for high-precision manual rework. |

| Precision Machining | Technical cleanliness and particle contamination audits. | EVO Cam II with automated documentation. |

| Automotive Tooling | Measuring tight tolerances on stamping dies. | LVC Series for automated CNC metrology. |

Application Note: Eliminating Ambiguity in Aerospace Machining

The Problem: A Tier-1 aerospace supplier struggled with “false rejects” on turbine blade edges. 2D digital systems couldn’t distinguish between surface discoloration and actual structural burrs.

The Solution: Implementation of the ProteQ VISO. The system’s true 3D stereo view allowed inspectors to perceive the depth of features immediately.

The Result: The ambiguity was removed, reducing unnecessary rework by 22%. Furthermore, the ability to record 3D playback of the inspection provided an auditable trail for international compliance.

Local Support: Visit Us in Subang Jaya

Vision Engineering Malaysia is committed to supporting the “National Investment Aspirations” by providing world-class technical support directly to local manufacturers.

Vision Engineering & Trading Sdn Bhd

P-03A-20, Impian Meridian,

Jalan Subang 1, USJ 1,

47600 Subang Jaya, Selangor Darul Ehsan.

Ready to see the difference?

Contact our local experts today to ensure your production line meets the global standard for precision.

- Request a Quote – Get tailored pricing for the ProteQ VISO or our metrology suite.

- Book an On-Site Demo – We bring our systems to your factory in Penang, Johor, or Klang Valley.

- Technical Consultation – Speak with an application engineer about your specific measurement challenges.

Contact Vision Engineering Malaysia

Tel: +603 5103 7525