Empowering Malaysia’s Electronics Hub: Precision Inspection & Measurement

As a global leader in “Silicon Valley of the East,” Malaysia’s electronics sector demands uncompromising quality. From high-speed SMT assembly and advanced semiconductor packaging to the final QC of complex PCBAs, Vision Engineering Malaysia provides the ergonomic and high-precision tools necessary to eliminate defects and boost throughput.

Our Electronics Solutions Suite

We specialise in eyepiece-less technology, which allows operators to work faster, more accurately, and with significantly less fatigue than traditional binocular microscopes.

1. Optical & 3D Stereo Inspection

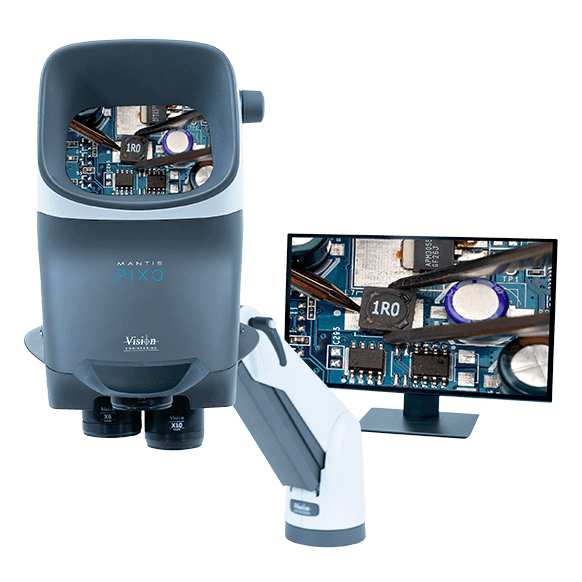

Mantis (3rd Gen): The industry standard for PCB rework and hand assembly. Its patented 3D image gives operators the depth perception needed for precise soldering and component placement.

Lynx EVO: High-productivity stereo microscope with up to 240x magnification. The 360° Rotating Viewer allows for “look-around” inspection of SMT solder joints, hidden leads, and through-holes without moving the board.

2. High-Definition Digital Visualisation

ProteQ VISO: The world’s first glasses-free digital 3D system which delivers a 3D image on a flat screen, that can be shared live between colleagues and supply chain partners. Perfect for remote collaboration between Penang R&D and overseas headquarters, providing real-time 3D images of microscopic defects.

EVO Cam II / HALO 4K: Ultra-high-definition (or high definition) digital microscopes for rapid documentation. Capture 4K images and video directly to USB or PC for instant traceability in IATF 16949-compliant environments.

3. Non-Contact Metrology

Swift PRO: A powerful 2-axis and 3-axis measurement system. Ideal for measuring delicate electronic components where physical contact is impossible, such as lead frames and micro-connectors.

LVC Series (CNC): Fully automated measurement for high-volume batch testing. Program your routines once and let the system verify thousands of components with micron-level accuracy.

Applications & Benefits for the Malaysian Market

| Process | Challenge | Vision Engineering Solution |

| SMT Rework | High operator fatigue leading to solder bridges. | Mantis – Superior ergonomics for 8-hour shifts. |

| Semiconductor | Inspecting wire bonds and die attaches in 3D. | DRV-Z1 – High-resolution 3D without eyestrain. |

| BGA Inspection | Viewing under-ball solder connections. | Lynx EVO – 360° oblique viewing at 34°. |

| QC Auditing | Fast documentation for quality reports. | EVO Cam II – One-click 1080p/4K capture. |

| Precision Stamping | High-volume dimensional verification. | LVC Series – Fully automated CNC metrology. |

Application note: Boosting Throughput in PCBA Rework

Customer: Tier-1 Electronics Manufacturer

The Problem: The client reported high staff turnover and a 12% rework rejection rate due to “visual fatigue” caused by traditional binocular microscopes.

The Solution: A full transition to Mantis ergonomic workstations.

The Result: Rejection rates dropped to under 4% within three months. Operators reported higher comfort levels, and the company saw a 20% increase in daily throughput as workers maintained high concentration levels for longer periods.

Local Support & Demonstration Centre

Vision Engineering & Trading Sdn Bhd provides full local support, including technical training, calibration services, and application consultations.

Visit Our Malaysia Office:

21-G, Jalan Putra Mahkota 7/8C,

Putra Heights, 47650 Subang Jaya,

Selangor, Malaysia.

Take Action Today

Ensure your production line meets the highest global standards. Contact our Subang Jaya team to:

- Book an On-Site Demo: We will bring our systems to your factory for a live trial.

- Request a Quote: Get competitive pricing for single units or full factory outfitting.

- Application Audit: Let our engineers help you find the right system for your specific PCBA or semiconductor challenge.

Contact Vision Engineering Malaysia

Tel: +603 5103 7525