Precision Inspection & Metrology Solutions for Malaysia’s Industry 4.0

In Malaysia’s competitive manufacturing corridors—from the high-tech hubs of Penang and Kulim to the industrial heartlands of the Klang Valley and Johor—precision isn’t just a goal; it’s a requirement.

Vision Engineering delivers world-leading ergonomic microscopes, digital 3D visualisation, and non-contact metrology systems designed to improve throughput and accuracy in Malaysia’s key export sectors.

EMS & Electronics Manufacturing

Zero-Defect QA/QC for the “Silicon Valley of the East”

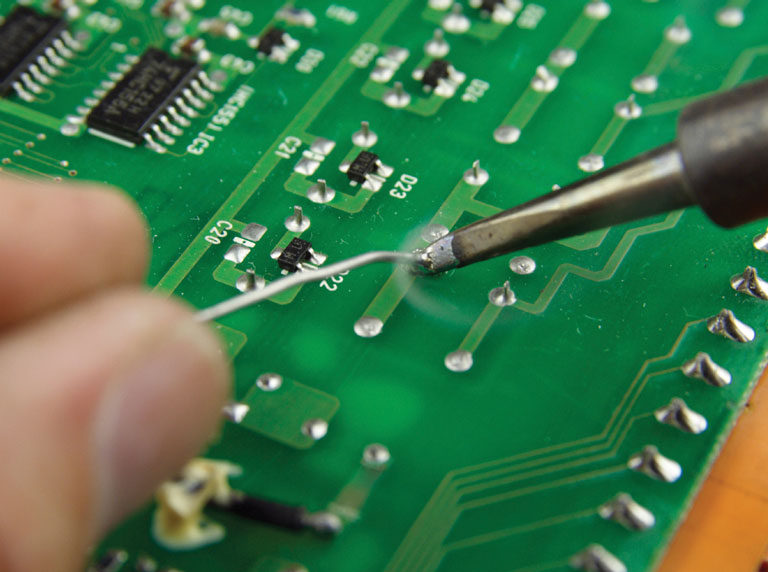

Malaysia’s EMS sector demands high-speed, high-accuracy inspection. Our systems are the industry standard for PCB assembly, SMT inspection, and In-Line Quality Control.

- Rework & Preparation: The Mantis ergonomic stereo microscope is the staple of Malaysian electronics benches, offering “eyepiece-less” technology that allows operators to wear safety glasses and move freely, reducing fatigue during long shifts in Bayan Lepas or Batu Kawan.

- High-Detail Inspection: The Lynx EVO provides stunning 3D optical imaging for complex PCB troubleshooting and IQA (Incoming Quality Assurance).

- 3D Digital Inspection: For remote collaboration between Malaysian plants and global R&D centres, the DRV-Z1 (Deep Reality Viewer) creates a full 3D digital image without glasses, perfect for inspecting solder fillets and component height.

Precision Engineering & Machining

Verifying Every Micron in Turned & Punched Parts

For precision workshops in Shah Alam, Puchong, and Nilai, maintaining tolerances on machined parts is critical for the global supply chain.

- Instant Measurement: The TVM-Series digital video metrology system allows for “field of view” measurement, perfect for the rapid inspection of turned parts, fasteners, and punched metal components.

- Surface Integrity: Use the EVO Cam II high-definition digital microscope to identify tool wear, surface burrs, and microscopic cracks with up to 300x magnification and ultra-fast frame rates.

- Dual-Optical Metrology: The Swift PRO combines a video measuring system with an ergonomic optical microscope, giving you the flexibility to measure both complex geometries and surface finishes on a single platform.

Medical Device Manufacturing

Compliance-Ready Inspection for Plastic & Electronic Components

As Malaysia cements its role as a global medical device hub, our systems ensure your facility remains compliant with ISO 13485 standards.

- Plastic & Moulded Parts: The DRV-Z1 allows for the inspection of transparent or reflective plastic medical components (like catheters and housings) with natural depth perception, making it easier to spot internal voids or flash.

- Automated Measurement: The LVC-Series (Large View CNC) video measuring systems provide fully automated inspection for batches of medical components, ensuring 100% repeatability for critical dimensions.

- Micro-Electronics in Med-Tech: Utilize the Lynx EVO for the assembly and inspection of delicate sensors and wearable medical electronics.

Automotive Component Inspection

Optimising Tier 1 & Tier 2 Automotive Supply Chains

Supporting the supply chain ecosystem of Proton, Perodua, and global OEMs in Malaysia, our systems provide the structural clarity needed for safety-critical components.

- Fast, High-Resolution Inspection: The Makrolite 4K digital microscope provides UHD resolution for inspecting engine components, ECUs, and transmission parts, allowing for detailed failure analysis and documentation.

- Non-Contact Measurement: The LVC400 is ideal for measuring larger automotive stampings and complex plastic mouldings without the risk of part deformation.

Vision Engineering Systems: Selection Matrix for Malaysian Industry

| Application | Recommended System | Key Advantage |

| SMT Rework | Mantis | Unmatched ergonomics for high-volume shifts. |

| Precision Measurement | TVM-Series | Instant “place and measure” for turned parts. |

| 3D Digital QA | DRV-Z1 | Glasses-free 3D for collaborative failure analysis. |

| Automated QC | LVC-Series | High-speed CNC measurement for batch medical/auto parts. |

| HD Documentation | EVO Cam II | 1080p/60fps imaging for rapid surface inspection. |

Why Vision Engineering in Malaysia?

- GEO Advantage: We understand the local landscape. Our solutions are used across Penang’s Free Industrial Zones, Selangor’s technology parks, and Johor’s Iskandar region.

- Ergonomics for Productivity: In a tight labour market, our eyepiece-less technology helps Malaysian firms retain skilled operators by improving comfort and reducing eye strain.

- Local Technical Support: Access expert calibration and technical support through our certified Malaysian distribution network.

Enhance Your Production Quality Today

Ready to upgrade your inspection capabilities in Penang, Kuala Lumpur, or Johor Bahru? Contact our regional specialists to schedule a site demonstration or a virtual “live” demo of our 3D visualisation systems.

Vision Engineering Malaysia Office:

P-03A-20, Impian Meridian,

Jalan Subang 1,

USJ 1, 47600 Subang Jaya, Selangor Darul Ehsan,

Malaysia.

Ergonomics. It’s just right.

‘Ergonomics’ is the study of people’s efficiency in their working environment. The term, which stems from the Greek words ergon (work or labour) and nomos (natural laws), expresses an ideal which informs everything that Vision Engineering designs and makes.

Our passion for improving operator efficiency through ergonomic design is what sets our technology apart from the competition. It’s a philosophy which enables superior accuracy, efficiency and productivity. And you can see it for yourself in our industry leading products, including Mantis, Lynx EVO and DRV-Z1.

Ergonomic working position

Good ergonomic design isn’t just nice to have, it makes good economic sense, too. Improving the ergonomic functionality of your microscopy equipment reduces the risk of poor efficiency, more errors and higher absenteeism.

Operator health and productivity

When viewing subjects under an ordinary binocular microscope, users need to maintain an uncomfortable static position. Over a period of time, this can lead to discomfort, which has a measurable impact on the efficiency and health of users. Eyestrain, muscle cramps and repetitive strain injuries are a risk when microscopes are used in this way.

World-class innovation

Vision Engineering has been leading the world with pioneering technology and award-winning innovations since 1958. In 2020 we were recognised by the Queen’s Award for Innovation, for our Lynx EVO high magnification, eyepiece-less stereo microscope. Now and in the years ahead, we will maintain an unswerving commitment to innovation, ergonomic design and improved user productivity.