Precision Inspection for Life-Saving Innovation: Medical Device Solutions in Malaysia

As a global leader in medical device manufacturing—responsible for over 60% of the world’s catheters and a significant portion of international surgical instruments—Malaysia’s medical industry demands absolute compliance and zero-defect quality.

Vision Engineering Malaysia provides the ergonomic 3D visualisation and metrology tools essential for ISO 13485 and MDA (Medical Device Authority) compliance. From stent inspection to surgical tool measurement, our suite ensures that every component meets the highest standards of patient safety.

Our Medical Device Product Suite

We specialise in “eyepiece-less” and digital 3D technology, providing the depth perception required for intricate medical assemblies without the fatigue of traditional microscopes.

1. NEW: ProteQ VISO | Next-Gen 3D Digital Stereo Inspection

The ProteQ VISO is our flagship digital platform, combining true 3D stereo vision with digital collaboration.

- Glasses-Free 3D: View fine features of stents and guide wires in high-definition 3D without headsets.

- Laminar Flow Ready: Its long standoff distance and separate display options make it ideal for use within cleanroom environments and safety cabinets.

- Auditable Traceability: Capture 3D video and images directly to your network for clear, defensible evidence during quality audits.

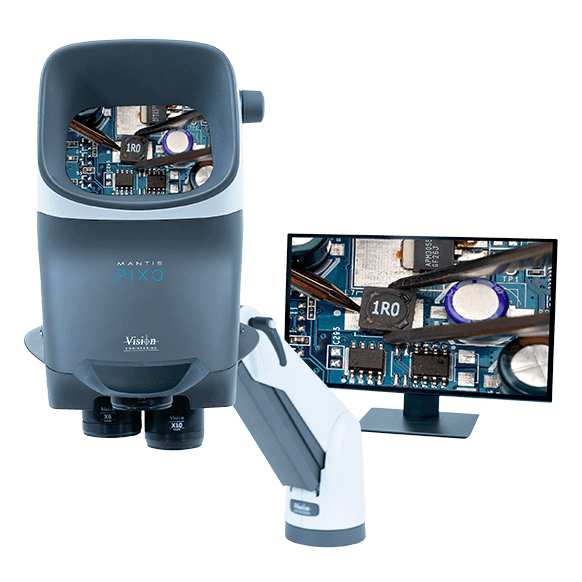

2. Mantis (3rd Gen) | The Standard for Surgical Tool Rework

The iconic “heads-up” stereo microscope. It provides the natural hand-eye coordination needed for deburring bone screws, polishing implants, and assembling complex delivery systems.

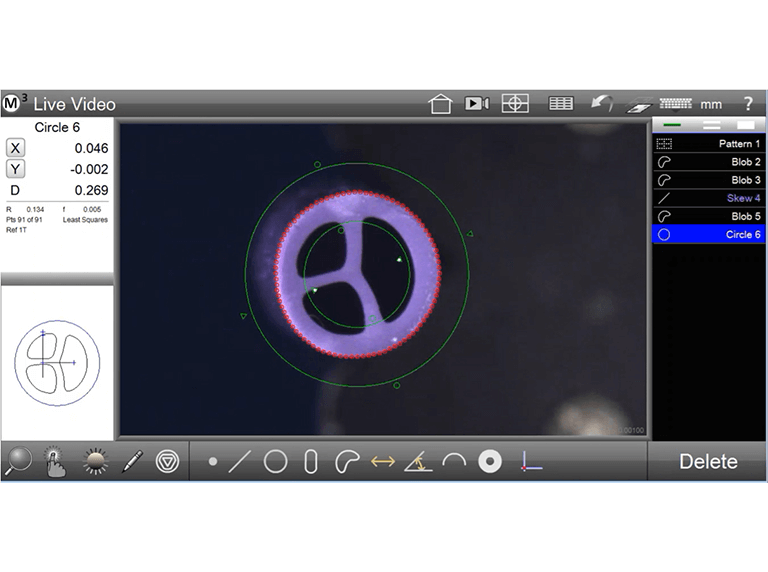

3. LVC Series & Swift PRO | Non-Contact Metrology

Precision measurement for delicate medical components that cannot be touched. Perfect for verifying the wall thickness of multi-lumen tubing and the geometries of orthopaedic implants.

Applications & Benefits for the Malaysian Market

| Medical Application | Technical Challenge | Vision Engineering Solution |

| Catheter & Guide Wires | Detecting microscopic surface cracks and kinks. | ProteQ VISO – Superior depth perception for surface inspection. |

| Orthopaedic Implants | Measuring complex curves and thread tolerances. | LVC Series – Automated CNC measurement with micron accuracy. |

| Stent Inspection | Checking for burrs and coating uniformity. | Lynx EVO – 360° rotation to view all angles of the stent. |

| Surgical Instruments | High-volume inspection of forceps and scissors. | Mantis – Ergonomic design to prevent inspector fatigue. |

Application Note: Enhancing Traceability in Catheter Production

The challenge: A leading manufacturer requires a way to document defects found during the inspection of high-precision cardiovascular catheters. Traditional 2D monitors often “flatten” the image, making it difficult to prove the severity of a surface void during audits.

The Solution: Implement ProteQ VISO. Because it records and plays back in true 3D, quality managers can see the depth of the void just as the inspector does on the line.

The Result: A 100% auditable digital trail for high-risk components, significantly shortening the time required for regulatory reviews and improving the internal “Golden Sample” training library.

Local Support: Serving Malaysia’s Medical Hubs

Vision Engineering Malaysia is committed to supporting local manufacturers from our Subang Jaya headquarters. We understand the local regulatory landscape and provide HRD Corp-claimable training for your quality teams.

Vision Engineering Malaysia Office:

P-03A-20, Impian Meridian,

Jalan Subang 1,

USJ 1, 47600 Subang Jaya, Selangor Darul Ehsan,

Malaysia.

Schedule Your Demonstration Today

Ensure your quality control processes are ready for the next level of medical innovation:

- Book an On-Site Demo: We bring the ProteQ VISO to your facility.

- Request a Quote: Get competitive pricing for your next QC upgrade.

- Application Audit: Let our engineers help you explore our full range of ISO-compliant tools.